Sweet Gazoil

Solutions for the treatment of waste plastics and waste/used oils

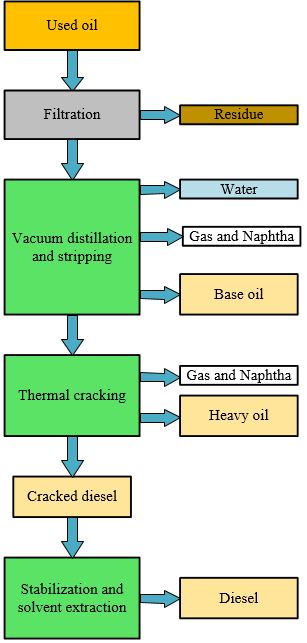

Our patented Hybrid Process combines the best of the rerefining and cracking processes, having few of their drawbacks. It has 3 main parts:

Like basic re-refining the Hybrid Process distills the feedstock so as to recuperate the base oils. However, the Hybrid Process is much less prone to fouling than present systems (fractionators, thin film evaporators). This eliminates the need to make selective collections of oils, perform extensive testing on the arriving feedstock or pre-treat the oils.

The oils that are left after the distillation are fed into our patented anti-fouling rotating kiln reactor to perform a Surface Flash Cracking. Each oil droplet takes the heat it needs to crack and vaporize from the plates where coke can deposit without affecting heat transfer. The reactor residence time is only a few minutes, whereas in other systems it goes from a few hours to 10+ hours. In the reactor, the metals and sulphur released by the cracking of additives combine with the coke to make an inert, non-leachable powder. The powder is easily separated from the fuel vapors as they exit the reactor, before the oil products are condensed.

Like fuels produced in other cracking processes, the diesel fuel obtained is unstable. This means that, over time, it will produce gums and polymers and its color will turn from light yellow to dark brown. In refineries, unstable oil is hydrotreated to stabilize and desulphurize it, which is very expensive. The Hybrid Process uses patented solvent extraction process that utilizes a recycled impure solvent and that operates at ambient temperature and pressure. It is a relatively inexpensive extraction process as the solvent doesn’t need complete regeneration and can have a small amount of residual sulphur and other impurities.