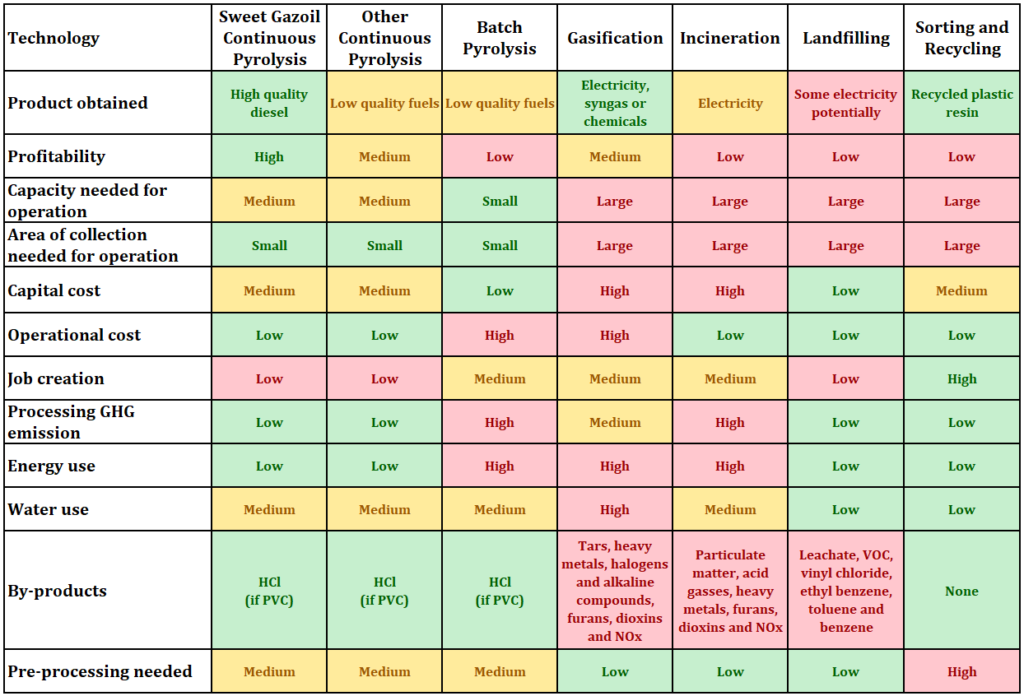

Sweet Gazoil Continuous Pyrolysis Advantage

Our patented reactor is specialised to prevent fouling and allow for a continuous operation. Through anti-fouling technologies, we can reduce operational costs while improving performance and product quality. The reactor performs a Surface Flash Cracking of very small particles on clean reaction sites in the absence of any liquid phase. This minimizes the entrainment of contaminants, prevents the saturation of the vapors, and allows for a more effective removal of solids from the vapors. The small particles and clean reaction sites also allow for a tight control on the reaction temperatures, therefore optimizing the products obtained (higher yield of diesel). Equipped with a specialised small-scale distillation column and other patented purification and stabilization equipment, our micro-refineries can obtain high quality fuels from low quality feedstocks.

- The reactor operates in the absence of air (oxygen), minimizing the production of toxins (furans and dioxins) and greenhouse gasses.

- The product is in the form of high quality, easily transportable and readily saleable ultra-low sulfur diesel.

- The units are profitable at small-scales, requiring very little land (1000 m2), reducing transportation costs and emissions.

- Units are energetically self-sufficient, as all the energy needed is provided by about 10% of the energy in the plastics or oils.

- The ultra-low sulfur diesel produced through the process emits 2 to 5 times less greenhouse gasses than the same fuel produced from crude in oil refineries.

Comparison Against Batch Pyrolysis

The process of turning plastics into fuels is not new. The Chinese have been doing it for at least 15 years. It has typically been done as a batch process, in which a large volume of liquid plastics is cracked in a large heated vessel over the course of 10+ hours. First, the plastics closer to the walls crack, causing the walls to become coated in coke and solid residues. This reduces heat transfer and the ability to control reaction temperatures. The product vapors also have to pass through the liquid plastics, which causes them to become saturated and making the removal of solids from vapors much less effective. Finally, in a batch process, the products cannot be separated using a distillation column and rely on using a series of condensers, further reducing the product quality.

- The batch process has higher energy use due to start-ups and shut-downs requiring equipment to heat up and cool down. The extra consumption of energy also means that the process emits more greenhouse gasses.

- For the same volume of feedstock, batch processes require more equipment, as they are less productive than a continuous process.

- Profitability is also lower than the continuous process because of the extra operational costs and lower quality products.

Comparison Against Gasification

Gasification is similar to pyrolysis but can intake a wider variety of feedstocks (organics, plastics, municipal solid waste) and operates at much higher temperatures (750°C to over 1100°C), breaking the feedstock molecules down to much smaller products (CO, CO2, H2, H2O, CH4). These products are in the form of syngas which, once properly cleaned and processed, can be sold as is, or can be transformed into other products (methanol, ethanol, biomethyl acetate, etc.), or can be used to power a generator to produce electricity.

- Typical gasification can obtain from 650 to 1000 kWh of electricity from 1 ton of waste, whereas the pyrolysis of only the plastic fraction of that waste (18 wt%) can obtain fuels having around 2000 kWh of energy (1600 kWh in the form of diesel).

- In gasification, the feedstock is partially oxidized (combusted) in the mild presence of oxygen, causing the production of more toxic compounds (furans, dioxins, NOx) and greenhouse gasses than pyrolysis.

- The high temperatures and high variability in feedstock cause the production of tars, heavy metals, halogens and alkaline compounds, which must be treated using expensive equipment.

- Since the processing temperatures are high and more equipment is needed, much more energy is consumed and the process is very expensive.

- Since capital and operational costs are so high, the operations must be large scale.

- Even using economies of scale, gasification plants are only competitive with landfilling and operate at a loss, requiring tipping fees to be economically viable.

- Since the process accepts a wider variety of feedstock and uses reactors which are subject to fouling, the process is more subject to shut-downs and requires more maintenance.

Comparison Against Incineration

Incineration simply combusts the waste feedstock to produce electricity. Its is an older technology that is less efficient than gasification and is often stated to produce about 500 kW of power per ton of municipal solid waste.

- The large amount of oxygen used for combustion causes the production of large quantities of CO2 and toxins (furans, dioxins and NOx), while the decomposition of the material produces particulate matter, acid gasses and heavy metals.

- Plants are expensive, requiring a lot of pollution abatement equipment.

- The main water consumption for the process is water used for pollution abatement equipment and, while the process requires little energy input, it also supplies less energy than pyrolysis and gasification.

- Plants operate at a loss, requiring tipping fees to operate, even at large scales.

Comparison Against Landfilling

In landfills, waste is dumped and some treatment is done to minimize pollution. Some materials can be recovered and some electricity can be generated from the methane emitted from the decomposition of waste.

- Plastics are a particularly bad feedstock for landfills, as they occupy a lot of volume and are amongst the items that take a longest time to decompose (100 to 1000 years).

- Through the decomposition of garbage, landfills emit a large amount of greenhouse gasses in the form of methane, while smaller quantities of volatile organic compounds (VOC), vinyl chloride, ethyl benzene, toluene and benzene are also emitted.

- Leachate (containing organic and inorganic chemicals, heavy metals and pathogens) is also produced and can pollute water sources.

- Pollution abatement technologies are used to minimize environmental harm.

- Landfills require large capacities and areas to operate.

- Although capital costs are relatively low, landfills require tipping fees to subsidize operations (even if some electricity is produced).

Comparison Against Sorting and Recycling

Although recycling waste plastics is typically seen as the superior process, it is not as simple as it seems.

Cleaned and sorted plastics obtained from material recovery facilities (MRFs) are sold for a small fraction of the price of the original resin and even a fraction of the price of diesel fuel. Recycling plastics, either mechanically or chemically, often requires that each type of plastic is sorted from one-another and that the plastics be pure (over 99%). Purity, in this case, means the same type of plastics (ex: HDPE vs PET) and color. To purify and sort post-consumer plastics to the degree needed for recycling, the plastics must undergo a lot of processing. This is very costly and, if the post-consumer plastics are not sufficiently sorted and cleaned prior to collection, it is typically not cost-effective to attempt to recycle them. This is the reason why, in the past, large amounts of waste plastics were exported to China. Following China’s material ban, many material recovery facilities (MRFs) are having difficulties making profit from their waste plastics.

Currently, multi-component and multi-laminate plastics are being produced in increasingly large amounts. These types of plastics are near impossible to cost-effectively process into new plastic resin and typically end up in landfill.

- For the majority of post-consumer plastics, recycling is not cost-effective.

- Transportation of light materials (plastics) is extremely inefficient (larger emission of greenhouse gases and more expensive), thus increasing the size of MRFs or sorting operations for plastics to increase profitability is difficult.

- Even sorted and cleaned plastics, coming from MRFs, are a fraction of the price of the original resin. It is even significantly lower than the value of diesel.